Systemised Improvements

Ongoing Support

Services

Services

Practical customised solutions to suit your business.

People

In role Coaching and Mentoring of your team

Development Plans

Succession Planning

Time & Attendance

Quality

Quality Management System

Attain and Sustain ISO9001:2015 Certification

Error Proofing

Engineering Change Management Through Operations

Productivity

Increasing Output & Performance

Setting and monitoring SMART Targets

Operational Measurement & Reporting

Stock Accuracy

Stocktake Preparation

Daily Cycle Counting System

Delivery

Internal Performance Analysis

External Performance Analysis

Measurement & Reporting

Cost

Labour Structure Assessment

Factory / Warehouse Space Optimisation

Storage Solutions

Factory / Warehouse Relocations

Supply Chain Analysis and Optimisation

Budgeting

Capital Expenditure Proposals and Analysis

Improvements

Continuous Improvement System

Operational Health Check & Current State Assessment

Strategic Planning

Executing Improvement Projects

Auditing of All Operational Systems

LEAN Tools

Continuous Improvement

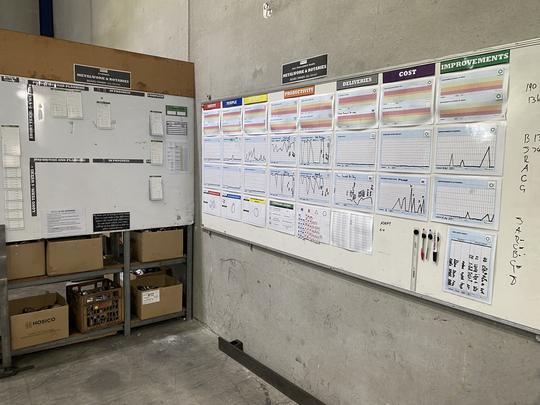

Visual Management

Practical 5S / Housekeeping

Structured Problem Solving

Standardised Work

Go and See Walks

One Piece Flow

Just in Time Production

Hoshin Kanri

Kanban

Andon

Advisory Board Support

Monthly Operations Advisory Board Meeting Participation

Report Writing

Report Analysis

Strategic Planning

Operations Budgeting

Gallery

Gallery

Please see below for some of our example projects

About Us

About Us

Steve Tabone has invested over 20 years in Operational roles across Manufacturing & Distribution with demonstrated success in both people and business performance. Steve’s career evolved from shop floor roles to executive leadership through his ability and genuine respect and care for people. These roles included administrative functions such as Scheduling, Purchasing, Specification, Quality then to Production Supervisor positions before entering Management in the roles of Purchasing Manager, IT Manager, Project Manager, Manufacturing Manager, Operations Manager, then General Manager of Lotus Doors and more recently Operations Director for Aluminium Industries of Australia.

Steve was first introduced to Operational Excellence and LEAN in 2012 and has since successfully transformed Operations for numerous companies through his passion for continuous improvement and visual management. In addition he has delivered several major projects which contributed to overall business success. These included Site relocations, site expansions, supply chain optimisation including both local and overseas, outsourcing, attaining and maintaining ISO9001:2015, ERP implementations, optimisation of existing ERP installations and many more waste elimination projects.

The decision to launch SLIM Solutions was made in 2022 with the main focus being that Steve wanted to utilise his skills and experience to really make a difference to multiple companies in Manufacturing & Distribution through improving their Operations. This includes improving their people, processes and systems to ultimately achieve increased bottom line returns, which is only achievable with an unprecedented level of respect and discipline. That respect & discipline comes with Steve Tabone and SLIM Solutions Pty Ltd.